【Introduction of Sand and Aggregate Production Line】

We provide customers with high-performance, safe, environmentally friendly, and reasonable supporting equipment for the sand and gravel aggregate production line, as well as the design and construction plan of the sand and gravel aggregate production line! The R&D personnel of Shanmei matched the VSI sand making machine with other series of products of the company, and designed a complete sand making production line, which doubled the production efficiency of aggregate and greatly reduced the production cost.

【Application field】

It can be used for hard limestone, granite, basalt, river pebble, slag and other aggregates and artificial sand making operations. It is suitable for applications in hydropower, building materials, highways, urban construction and other industries. It is especially suitable for special construction fields such as production and processing of highway surface materials, high-grade highway pavement gravel, high-speed passenger dedicated line gravel aggregates, hydropower station gravel materials, port terminals and airport runways gravel materials. At the same time, according to different process requirements, various types of equipment are combined to meet the different process requirements of customers.

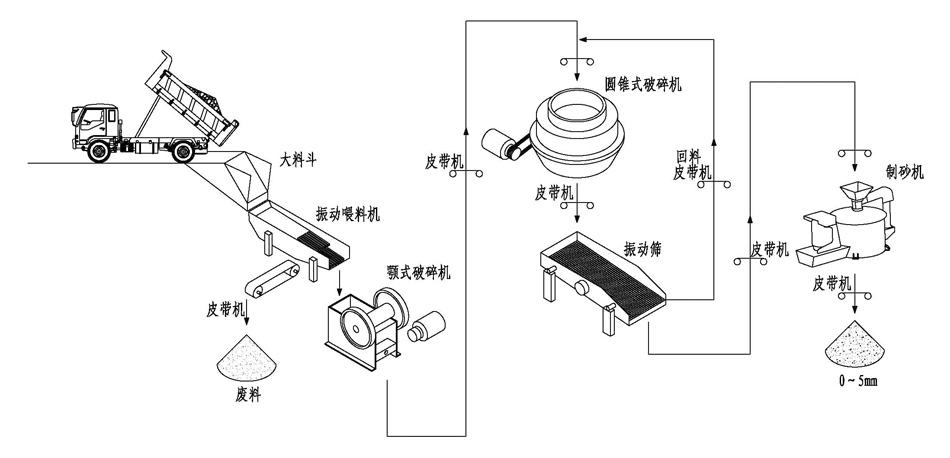

【Production process and flow chart】

Zhejiang Lizhi Machinery Co., Ltd. produces a full set of sand making production line equipment to provide you with comprehensive technical support. The configured stone production lines are carefully designed for customers based on on-site surveys or actual customer requirements, which fully embodies the rationality, effectiveness, and applicability of the design. Large processing capacity, low wear and tear, and low operating costs are its notable features. Strong technical strength and perfect service system are the guarantee for customers to purchase and use with confidence. According to different process requirements, various types of equipment are combined to meet the different process requirements of customers.

【Core Competence】

Performance characteristics:

1. The investment is only 1/3--1/5 of the traditional production line with the same processing capacity.

2. The production cost per ton of sand and gravel is only 1/3-1/4 of the traditional production line.

3. The degree of automation is high, and each shift requires less than 3 production personnel.

4. The investment payback period is short, usually within 3 months.

5. The product has uniform particle size, good shape and reasonable gradation, which fully meets the national construction sand standard.

Process flow of sand making production line: The machine-made sand production line is mainly composed of vibrating feeder, jaw crusher, impact crusher, vibrating screen, sand making machine and belt conveyor, centralized electric control and other equipment. In order to meet the different processing needs of customers, cone crushers and dust removal equipment can be equipped. The large stones are evenly sent to the jaw crusher by the vibrating feeder through the silo for coarse crushing. The coarsely crushed stones are sent to the impact crusher by the belt conveyor for further crushing; the finely crushed stones are conveyed by the belt conveyor It is sent to the vibrating screen for screening, and several different specifications of stones are screened out. The stones that meet the particle size requirements are sent to the finished product pile by the finished product belt conveyor; the stones that do not meet the particle size requirements are returned to the counterattack by the belt conveyor The crusher breaks again, forming a closed circuit for multiple cycles. The particle size of the finished product can be combined and classified according to the needs of users. In order to protect the environment, auxiliary dust removal equipment can be equipped.

Product performance characteristics:

(1) The finished sand particles have good shape;

(2) The finished sand has reasonable gradation and adjustable fineness modulus;

(3) All indicators of finished sand meet national standards and are high-quality concrete aggregates;

(4) The production cost of finished sand is low and the benefit is good.